For fabricators seeking to streamline steel structure processing, the HC Series laser cutting machine represents a versatile, multi-functional solution. To help industry professionals better understand its capabilities, we address the nine most common questions about this all-rounder system.

1. What materials can the HC Series process?

The HC Series handles a wide variety of materials, including structural profiles such as H-beams, I-beams, channels, and angles, as well as plates and square or round tubes. With the HC Series hybrid laser cutting model, users effectively get a profile cutter, tube cutter, and plate cutter in one machine—eliminating the need for multiple dedicated devices and significantly reducing equipment costs.

2. What is the processing range?

This machine supports profiles with a width of 100-12,000 mm, a width of 100-1,500 mm, and a height of 100-600 mm, offering a wider processing range than traditional profile cutting machines. For plate, it can process metal sheets up to 13,000 x 3,000 mm. For tubes, it can process square and round tubes ranging from 200 to 850 mm, with round tube processing capacity expandable to 100 to 1,200 mm.

3. How does it process profiles, plates, and tubes in one machine?

The HC Series comes standard with a 28-meter bed that supports multiple configurable stations. By adding a profile support unit, plate support table, and tube processing module, the system seamlessly switches between different material types. It integrates with Tekla software for fast drafting and performs operations such as cutting, beveling, hole punching, marking, and intersecting line cutting—all in a single setup.

4. What are the advantages over traditional H-beam processing?

Traditional H-beam fabrication requires separate sawing, drilling, beveling, and milling machines, often manned by 5–6 operators. The HC Series integrates loading, cutting, punching, beveling, locking, and unloading into one automated process, reducing labor, floor space, and handling while ensuring high precision and no secondary finishing.

5. How does the machine guarantee accuracy?

An intelligent deviation correction system measures the profile position and dimensions in real time, automatically adjusting the cutting path to prevent errors caused by material deformation or misalignment—ensuring consistent cutting and hole quality.

6. What about processing efficiency?

Unlike single-station machines that suffer from idle time during loading/unloading, the HC Series uses a multi-station design that enables continuous workflow. Operators can load plates or tubes in one station while the machine cuts profiles in another, dramatically reducing downtime and boosting overall productivity.

7. Does simultaneous loading/unloading affect cutting precision?

The machine’s floor rails and worktables are isolated, allowing loading and unloading operations to occur independently without impacting cutting stability or accuracy.

8. Can workstations be customized?

Yes. The HC Series supports both standard and custom workstation configurations. Customers can request tailored designs, and detailed drawings and installation guidance are available.

9. Can it be retrofitted onto a plasma cutting foundation?

The HC Series can be installed directly onto existing plasma cutting foundations without demolition, offering a cost-effective upgrade path to laser technology. An optional steel foundation is also available for new installations.

About KF Laser

KF Laser is a high-tech enterprise focusing on the research and development, production and sales of laser and machine tool equipment.Relying on cutting-edge technological innovation, the company is committed to providing customers with efficient and precise laser processing solutions. Its main products include fiber laser cutting machines, laser welding machines, laser marking machines, CNC machine tools and other equipment.

KF Laser adheres to the business philosophy of "quality first, customer first". Through continuous technological improvement and product innovation, it continuously improves the performance and reliability of equipment, meets customers' diverse processing needs, and provides customers with comprehensive technical support and solutions.

-

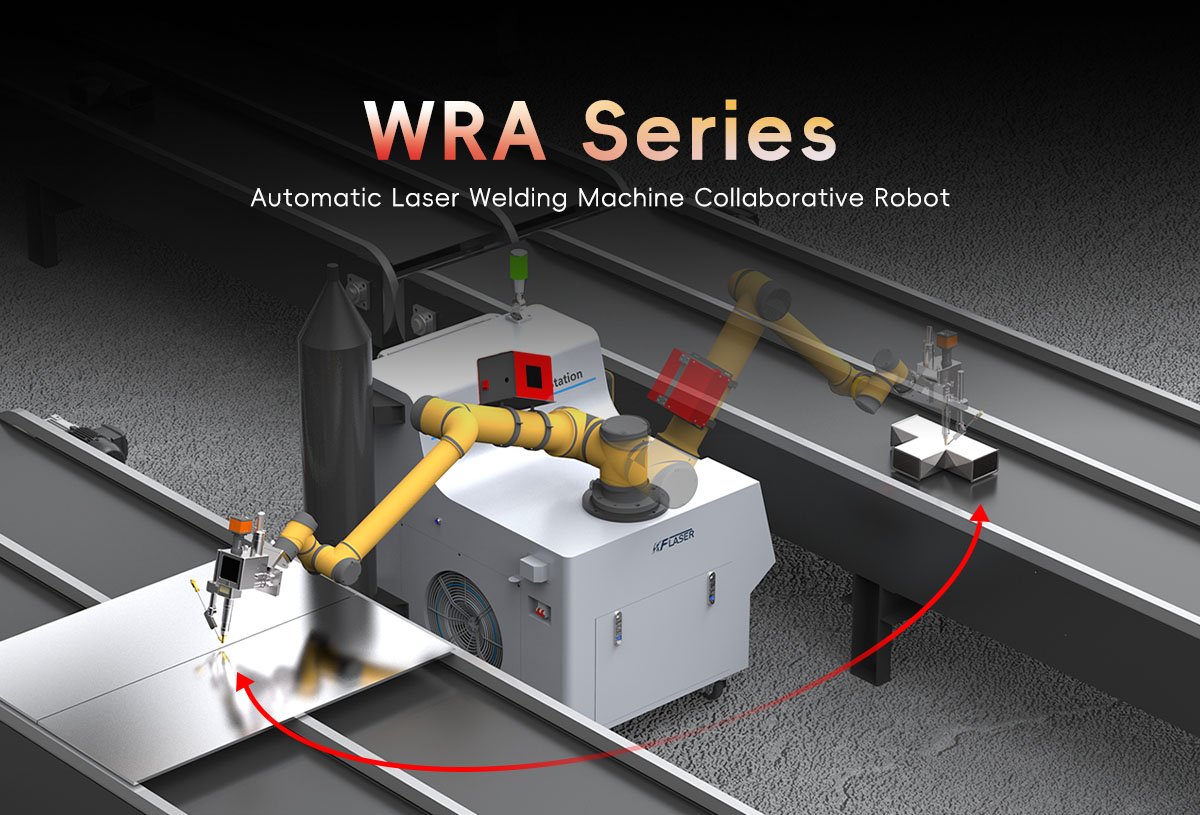

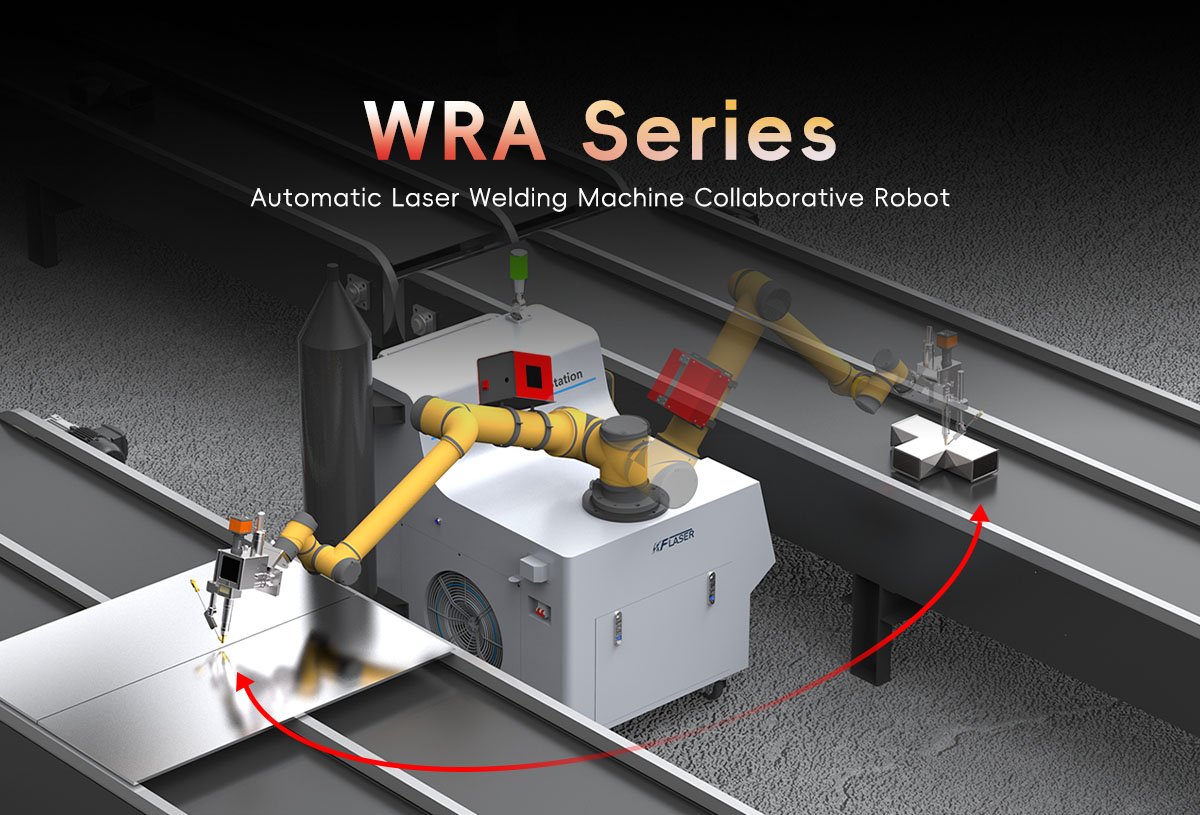

Recently, KFLASER's robotic arm laser automatic welding head has attracted attention in the metal processing field. This solution, with its superior flexibility, stability, and efficiency in welding complex 3D workpieces, has gained high recognition from numerous benchmark companies and is becomingProduct

Recently, KFLASER's robotic arm laser automatic welding head has attracted attention in the metal processing field. This solution, with its superior flexibility, stability, and efficiency in welding complex 3D workpieces, has gained high recognition from numerous benchmark companies and is becomingProduct -

Egyptian manufacturers praise KFLASER for its smooth delivery, reliable performance, and excellent local support.In July of this year, KFLASER successfully delivered a state-of-the-art TH Series dual-chuck tube laser cutting machine to a leading Egyptian manufacturer. Notably, the seamless deliveryProduct

Egyptian manufacturers praise KFLASER for its smooth delivery, reliable performance, and excellent local support.In July of this year, KFLASER successfully delivered a state-of-the-art TH Series dual-chuck tube laser cutting machine to a leading Egyptian manufacturer. Notably, the seamless deliveryProduct -

Chinese Innovation Supports Manufacturing Upgrade in South Africa's Industrial Hub Jinan, China – October 26, 2023 – KFLaser, a leading Chinese manufacturer of industrial laser equipment, has successfully delivered and installed a high-performance laser tube cutting machine-TH series for a promineProduct

Chinese Innovation Supports Manufacturing Upgrade in South Africa's Industrial Hub Jinan, China – October 26, 2023 – KFLaser, a leading Chinese manufacturer of industrial laser equipment, has successfully delivered and installed a high-performance laser tube cutting machine-TH series for a promineProduct