Simultaneous Cutting, Loading and Unloading

When cutting tubes, it can simultaneously initiate a new round of loading or finish the previous unloading,

bringing about an unprecedentedly efficient and smooth processing experience.

Simultaneous Cutting and Loading

Simultaneous Cutting and Unloading

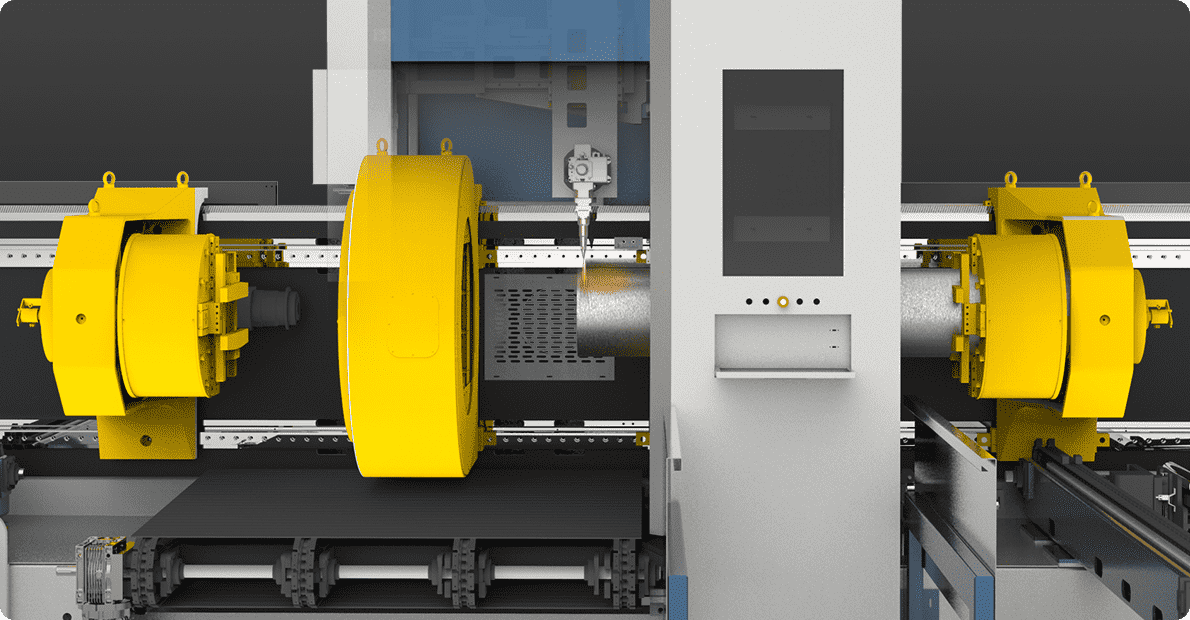

Four-Chuck Processing for Truly 0 Waste Material

The four-chuck structure allows the material to move forward or backward when cutting the last section of any length of pipe, achieving waste-free cutting.

Intelligent Cutting Modes Switching for All Processing Scenarios

According to different working conditions, the four chucks are intelligently paired and automatically switch processing modes.

TIV-3

Model

TIV-5

Model

30500*3600*2900mm

Dimension(L*W*H)

17500*2800*2900mm

Dimension(L*W*H)

12000mm

Maximum Processing Length

12000mm

Maximum Processing Length

12000mm

Unloading Length

12000mm

Unloading Length

20-360mm

Processing Pipe Size

40-550mm

Processing Pipe Size

6000-20000w

Power Support

6000-20000w

Power Support

1000kg

Chuck Weighing

1500kg

Chuck Weighing

60r/min

Chuck Rotation Speed

40r/min

Chuck Rotation Speed

60m/min

Maximum Idle Running Speed

40m/min

Maximum Idle Running Speed

0.6G

Maximum Idle Acceleration

0.3G

Maximum Idle Acceleration

Ultra-Large Cutting Range

Using a square-circle structure chuck, it can cut round tubes with a maximum diameter equal to the maximum side length of square tubes.

Performance Parameters

Laser Cutting Capabilities

Advantages Of Laser Cutting

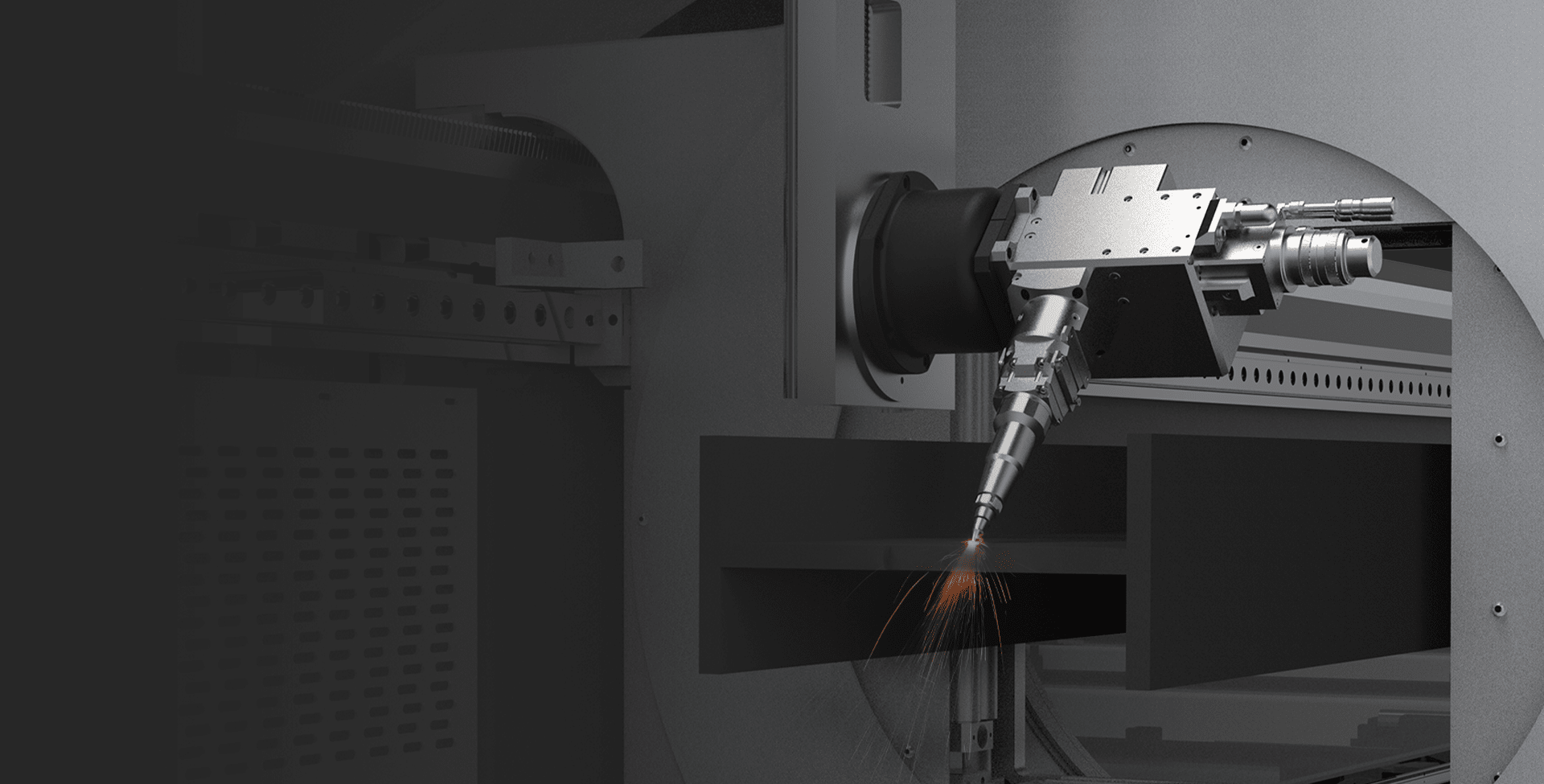

Maximum ±45° Bevel Cutting

3D Cutting Head

Three-dimensional Five-axis

Large-angle Swing Axis

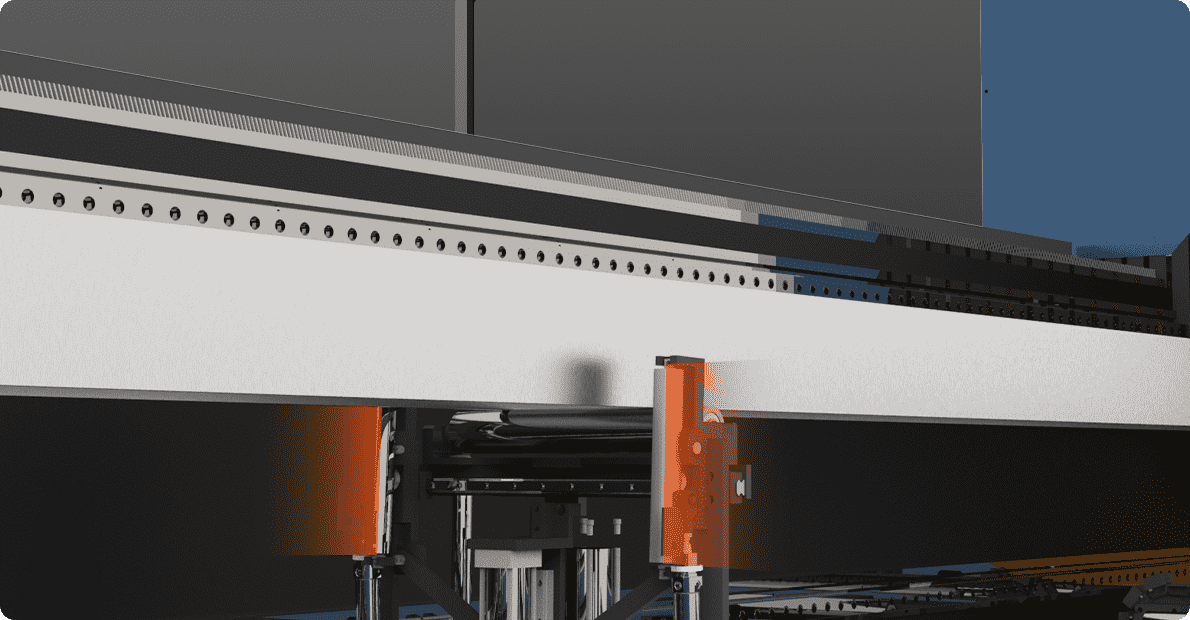

Follow-Up Rollers, Precision Leaped

Follow-up roller and intelligent centering support improve loading and unloading efficiency by 30%

Applicable Industries

Widely utilized in a diverse range of industries, including hardware accessories, construction machinery, medical devices, outsourced processing, and photovoltaic equipment.