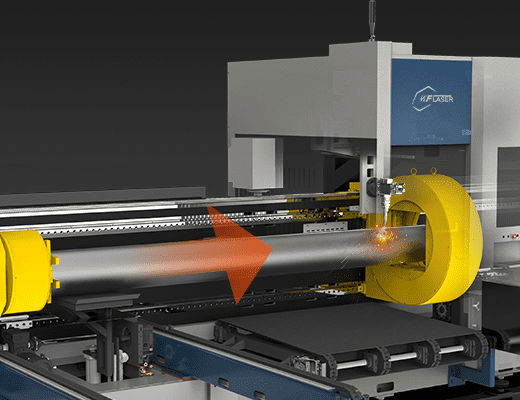

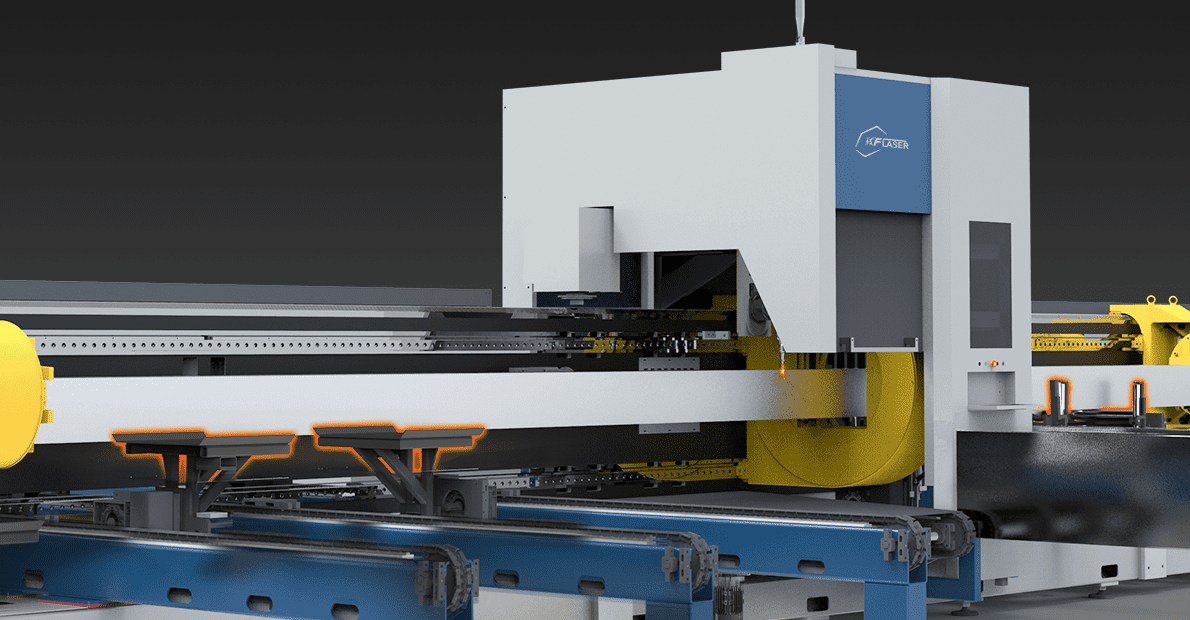

Simultaneous Cutting, Loading and Unloading

When cutting tubes, it can simultaneously initiate a new round of loading or finish the previous unloading,

bringing about an unprecedentedly efficient and smooth processing experience.

Simultaneous Cutting and Loading

Simultaneous Cutting and Unloading

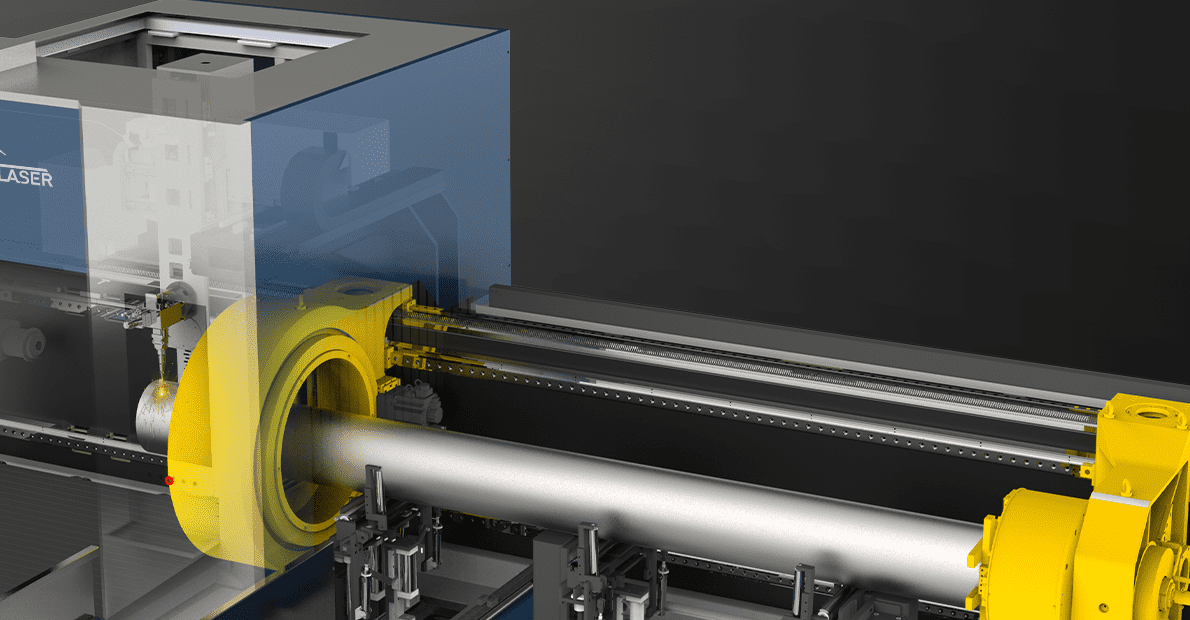

Three Chuck Processing for Truly 0 Waste Material

The three chuck structure allows the material to move forward or backward when cutting the last section of any length of pipe, achieving waste-free cutting.

Intelligent Cutting Modes Switching for All Processing Scenarios

According to different working conditions, the three chucks are intelligently paired and automatically switch processing modes.

TIII-3

Model

TIII-5

Model

17500*2800*2800mm

Dimension(L*W*H)

17500*2800*3300mm

Dimension(L*W*H)

6000mm

Maximum Processing Length

6000mm

Maximum Processing Length

3000mm

Unloading Length

3000mm

Unloading Length

20-360mm

Processing Pipe Size

40-550mm

Processing Pipe Size

6000-20000w

Power Support

6000-20000w

Power Support

1100kg

Chuck Weighing

2000kg

Chuck Weighing

100r/min

Chuck Rotation Speed

60r/min

Chuck Rotation Speed

75m/min

Maximum Idle Running Speed

60m/min

Maximum Idle Running Speed

0.8G

Maximum Idle Acceleration

0.6G

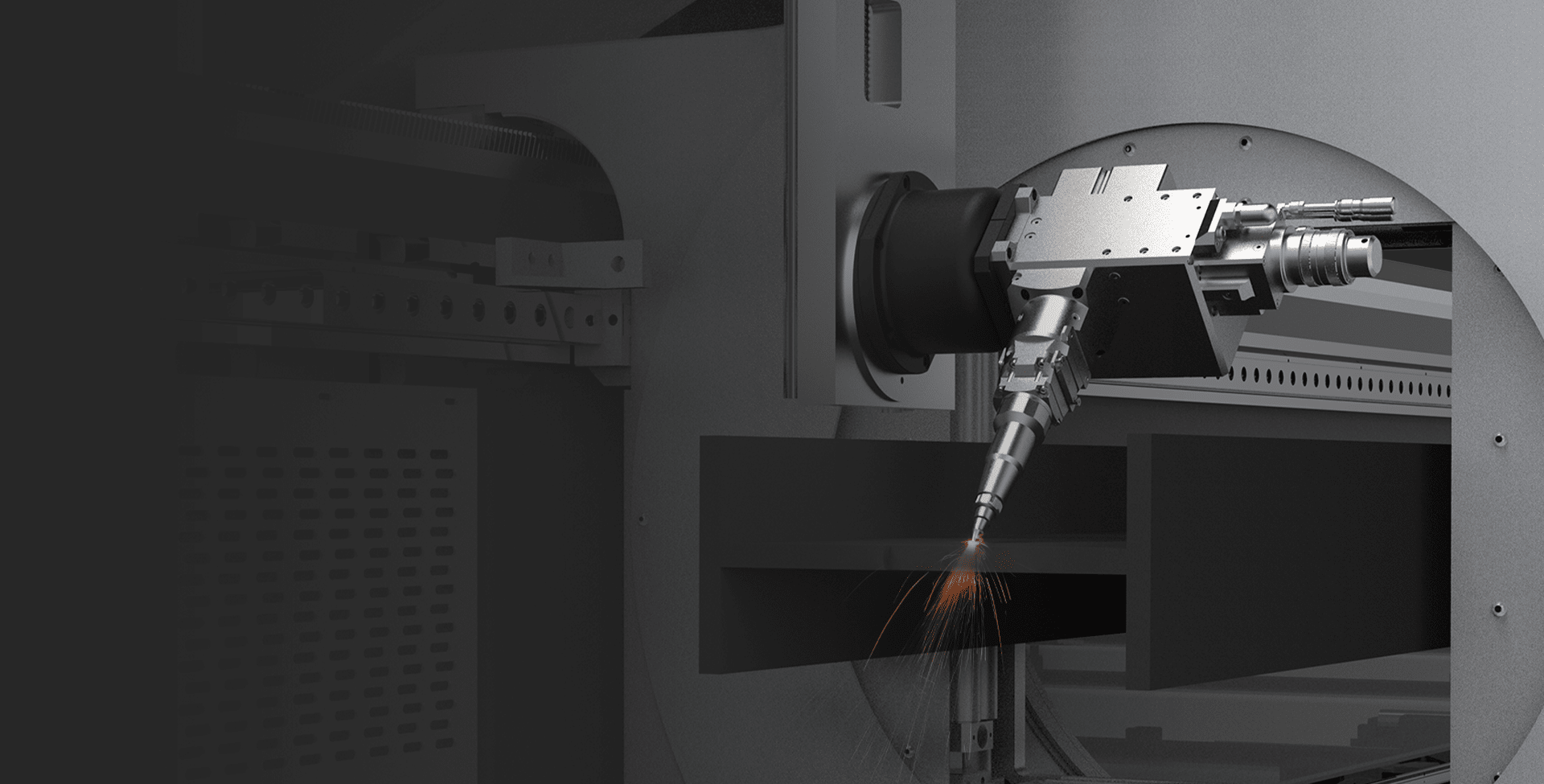

Dual-zone Tracking, Striving for Excellence

The feeding area is supported by a follow-up support plate, and the discharging area is supported by a follow-up roller.

Performance Parameters

Laser Cutting Capabilities

Advantages Of Laser Cutting

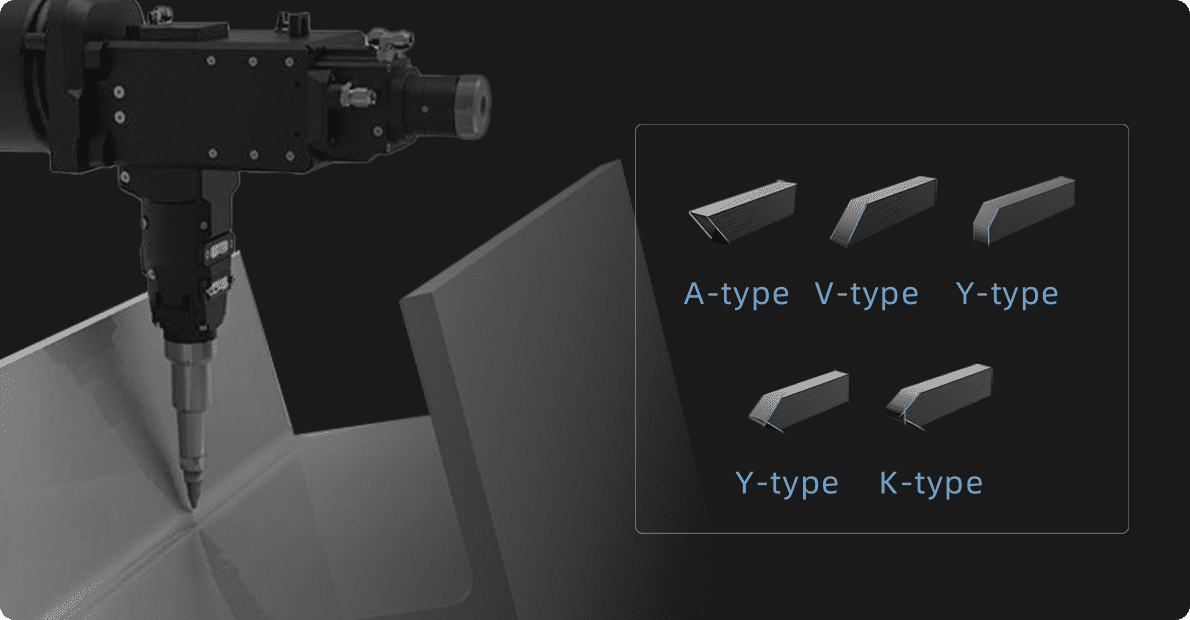

Maximum ±45° Bevel Cutting

3D Cutting Head

Three-dimensional Five-axis

Large-angle Swing Axis

Multiple Bevel Cutting

Support A-type, V-type, Y-type, X-type, K-type bevel cutting

Applicable Industries

Widely utilized in a diverse range of industries, including hardware accessories, construction machinery, medical devices, outsourced processing, and photovoltaic equipment.