In the field of industrial manufacturing, welding process is a key link that determines product quality. During the laser welding process, customers often face the following issues:

In the field of industrial manufacturing, welding process is a key link that determines product quality. During the laser welding process, customers often face the following issues:

1. Unstable welding quality, performance degradation at high temperatures, and high rework rate

2. The device has a single function and high purchase cost

3. Welding operations are complex, and the cost of training skilled workers is high

4. High end laser welding equipment is expensive and difficult for small and micro customers to afford

5. Slow after-sales service response, affecting production progress

In response to the aforementioned customer pain points and market challenges, KFLASER has launched the KFW series laser welding machine, which includes four types of welding machines, fully meeting the different needs of customers and bringing true welding high quality. It is suitable for the vast majority of welding scenarios in the market, allowing every user to afford high-end quality and five-star service welding equipment.

01.

Real Deep Fusion

Ensure high-quality welding

The KFW series adopts a mature and leading optical manufacturing solution, with an efficient and integrated cooling system inside. Each welding machine must pass a rigorous test of continuous full-power light output at 40°C for 500 hours, solving the problems of performance degradation and stability decline in ordinary welding equipment.

In terms of welding performance, the KFW series boasts a maximum penetration depth of 4-5mm and a welding speed of 50cm/min. Even with extended welding sessions lasting up to 24 hours, the penetration depth remains consistent, significantly enhancing production efficiency compared to traditional processes like gas shielded welding and argon arc welding.

02.

Versatile Performance

One machine solves four major problems

Traditional welding workshops often require the purchase of multiple pieces of equipment to handle welding, cleaning, rust removal, and cutting operations, which not only occupies valuable space but also increases equipment investment costs. The KFW series creatively combines four functions into one device, providing the value of four devices at the price of one:

1. Efficient welding: full penetration welding, one-time molding, no need for secondary repair, smooth and beautiful weld seam, quality certified by industry authorities.

2. Weld cleaning: quickly remove welding slag, oxides, etc. generated during the welding process to solve the problem of blackening of the weld.

3. Strong rust removal: Efficiently remove various rusted surfaces, leaving the welding surface smooth and clean.

4. Precise cutting: Support cutting of thin plates, fast speed, high precision, not easy to deform, meet most daily cutting needs.

This "four-in-one" design not only saves users 75% of the purchase cost, but also greatly improves the utilization rate of workshop space and work efficiency. Users do not need to switch back and forth between different equipment or travel to various workstations, truly achieving an efficient operation mode of "one machine for multiple purposes"

03.

Ultimate Ease of Use

Get started in half an hour

KFLASER is committed to making advanced laser processing technology more simple and easy to use. The KFW series completely breaks the high threshold of laser welding technology through three major innovative designs:

1. Intelligent process library: built-in perfect welding parameter database, users only need to select the material type and thickness, the system can automatically match the best welding parameters, without complex debugging.

2.7-inch touch screen: Intuitive visual interface, all parameters are clear at a glance, the operation logic is simple and clear, novices can operate independently after half an hour of training, and the welding effect is comparable to that of experienced welders.

3. Brand-new welding gun: Ergonomic design brings comfortable grip, and the weight of the welding gun has been reduced by 15%, making it less fatiguing for long-term operation.

4. Welding process upgrade: pulse spot welding, designed specifically for ultra-thin plate welding, can weld plates as thin as 0.2mm, avoiding the deformation and burn-through issues of traditional welding; wire breakage process upgrade, allowing novices to easily complete professional-level welding.

The KFW series is easy to operate and easy to learn. Even operators with no welding experience can master the skills in a short time and achieve welding results comparable to those of experienced welders. They can easily take up their positions without requiring welding certificates.

Truly deep fusion, truly good quality! The KFW series self cooling handheld laser welding has a wide range of application scenarios,

It can be used as the main model for various welding scenarios such as kitchenware, sheet metal processing, stainless steel products, air ducts, shelves, handicrafts, stair handrails, chassis and cabinets, furniture and household appliances.

Compared to similar products in the market, the KFW series has faster and better welding, simpler operation, and lower costs, providing you with a smoother, more efficient, simple, convenient, and cost-effective product experience for welding operations.

It redefines the value benchmark of water-cooled welding with quality and service, benefiting thousands of households in metal welding, contributing to the comprehensive popularization of laser welding technology and the upgrading and innovation of production methods, and promoting the quality improvement of the entire social productivity.

About KF Laser

KF Laser is a high-tech enterprise focusing on the research and development, production and sale so laser and machine tool equipment.Relying on cuting-edge technological innovation, the company iscommitted to providing customers with efficient and precise laser processing solutions. Its main products include fiber laser cutting machines,laser welding machines, laser marking machines,CNC machine tools and other equipment.

KF Laser adheres to the business philosophy of "quality first, customer first". Through continuous technological improvement and product innovation, it continuously improves the performance and reliability of equipment, meets customers' diverse processing needs, and provides customers with comprehensive technical support and solutions.

-

Customized Technology and Trusted Support Strengthen KFLASER's Commitment to Japanese ManufacturInnovation Designed with Customer NeedsKFLASER has consistently delivered differentiated, innovative laser solutions that precisely meet the needs of the local manufacturing industry, earning strong trustProduct

Customized Technology and Trusted Support Strengthen KFLASER's Commitment to Japanese ManufacturInnovation Designed with Customer NeedsKFLASER has consistently delivered differentiated, innovative laser solutions that precisely meet the needs of the local manufacturing industry, earning strong trustProduct -

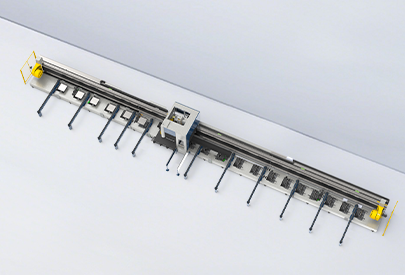

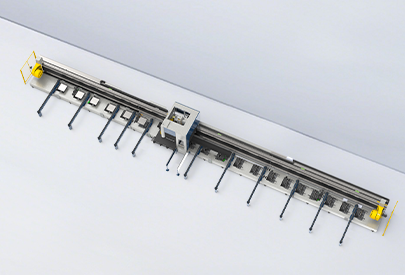

HELSINKI, FINLAND – July 2025 – KFLaser, a globally recognized innovator in intelligent laser cutting systems, today announced the successful commissioning of a high-power 12kW TIV Bevel Tube Laser Cutting Machine at a leading Finnish steel construction manufacturer. This installation represents a sProduct

HELSINKI, FINLAND – July 2025 – KFLaser, a globally recognized innovator in intelligent laser cutting systems, today announced the successful commissioning of a high-power 12kW TIV Bevel Tube Laser Cutting Machine at a leading Finnish steel construction manufacturer. This installation represents a sProduct -

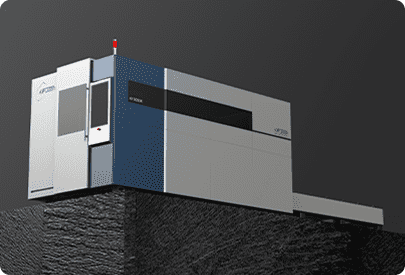

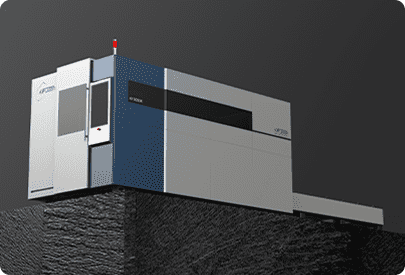

KF Laser proudly introduces its K Series Laser Cutting Machines, setting new industry standards with cutting-edge technology and innovative design. These machines combine precision, efficiency, and environmental sustainability,making them ideal for modern industrial applications.Key Features & InnovProduct

KF Laser proudly introduces its K Series Laser Cutting Machines, setting new industry standards with cutting-edge technology and innovative design. These machines combine precision, efficiency, and environmental sustainability,making them ideal for modern industrial applications.Key Features & InnovProduct